Guomao Group has been a manufacturer specializing in power transmission industry for 30 years with a wide product series including speed reducer boxes, gear motors, electric motors and become a bellwether in the intelligent automation.

Wide Range of Fields

We have established business relationship with leaders in various fields such as energy, mining, construction, logistics, pharmaceuticals, chemicals, machinery and robotics.

Wide Range of Applications

Our products are widely used in Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction works, Energy & Mining, Food & Beverage Shops, Hotels, Building Material Shops, Farms, Restaurant, Home Use, Retail, Food Shop, Advertising Company, Energy & Mining, Other.

Quality Assurance

Each batch of goods has a corresponding quality inspection report to solve your concerns about product quality.

Quick Transportation

We cooperate with professional sea, air and logistics companies to provide you with the best transportation solution.

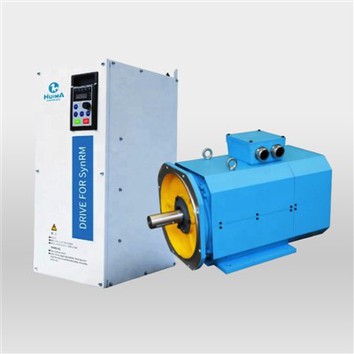

What Is Electric Motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. If you want to know the specifications and prices of Electric Motor, please contact us!

Efficiency

Efficiency is one of the biggest advantages of electric motors. Electric motors will typically convert more than twice the amount of electrical energy into mechanical energy, or motion, than traditional internal combustion engines. An electric motor generates torque by electric current and magnetic fields, whereas an ICE motor takes a longer amount of time to combust fuel and turn the crankshaft (in a vehicle). An electric motor can generate full torque when accelerating from a standstill, propelling ahead much faster and more efficiently than an ICE. The wide torque curve also eliminates the need for the traditional 4 - 7+ stages in a gearbox, as a single stage is sufficient.

With very few mechanical moving parts, compared to hundreds in an ICE motor, general maintenance is greatly reduced. Without a combustion engine, the need for regular servicing, oil changing, etc. becomes redundant.

Environmental and Health Benefits

There is no doubt that electric powered vehicles emit far less pollutants into the atmosphere than their combustion engine powered counterparts. For example, on average, an electric vehicle will emit around half as much carbon dioxide as an ICE vehicle, when considering its entire carbon footprint. Reducing emissions and creating a less polluted environment are clear benefits of electric powered motors, and as time and technology advance, they will most certainly become increasingly favourable over those that burn fuel.

Cost Effectiveness

Whilst the initial purchase price of many EV's is currently higher than that of their ICE counterparts, the running and maintenance costs are clearly much less. Electricity is of course not free, so factoring in the energy bill is a good idea if the car is to be charged at home, and users can benefit from many power providers offering free or heavily reduced power pricing periods overnight. The cost of electricity use can be further reduced at home by using renewable energy sources like solar panels. Charging stations in public places are free in many parts of New Zealand and around the world, while others require a small fee, and as more options for charging are introduced, costs could be reduced further.

Noise Pollution

Noise pollution is of course another great benefit of electric powered vehicles. Electric vehicles, including buses and trucks, run with minimal sound, so the effects of engine noise are greatly reduced. As EV's only emit road noise, some car manufacturers have taken to including false sounds in an attempt to make them safer around pedestrians in urban areas.

Regenerative Braking

The process of regenerative braking in an electric motor has several advantages. Regenerative braking recaptures kinetic energy largely lost as heat during braking and converts it back into electrical power in order to charge the battery. This in turn can potentially extend the driving range, meaning less time charging and more time moving. Regenerative braking also slows the car down, assisting with the job of traditional brakes. This in turn means less wear and tear, prolonging their life so fewer replacements are required.

Types of Electric Motor

DC Motors

A DC motor is any motor of a type of rotary electrical machine which converts electrical energy from direct current (DC) into mechanical energy. The most general types depend on the force created by magnetic fields. Almost all kinds of DC motors have some internal operation, either electronic or electromechanical, to change the current direction periodically in a part of the motor.

DC motors were the first kind of motor commonly utilized, as they can be powered from present direct current lighting energy distributing systems. DC motor speed may be controlled over a broad range, utilizing either a variable voltage supply or by altering the current strength in its field winding. Small DC motors are applied in appliances, toys, and tools. The universal DC motor can work on direct current but it is a light brushed motor utilized for portable appliances and power tools. Large DC motors are presently utilized in the propulsion of elevators and hoists, electric vehicles, and in drives for rolling mills for steel. With the arrival of power electronics replacement of DC motors with AC motors has been made conceivable in many applications.

12V Motors

A 12V DC motor is inexpensive and small, but powerful enough to be utilized for various applications. One property of a 12V DC motor is its operating voltage. When a battery powers a DC motor, low operating voltage is generally preferred because fewer cells are needed to achieve the specified voltage. However, at high voltages, electronic devices to drive a motor are generally more efficient. Although functioning is possible with voltage as low as 1.5V which goes up to 100, the most usual are the 12V DC motor, 6V DC motor, and 24V DC motor. Other key characteristics of a 12V DC motor include the operating torque, speed, current, and power.

Brushless Motor

A brushless motor is a type of DC motor (BL motor or BLDC motor), also referred to as an electronic commutated motor (EC or ECM motor). It could also be called a synchronous DC motor. This is a motor utilizing direct current electric power. It utilizes an electronic controller to turn on DC currents to the windings creating a magnetic field that successfully rotates in space and the permanent magnet rotor rotates by following. The controller adjusts the amplitude and phase of the DC current pulse to control the torque and speed of the motor. This control mechanism is a substitute for the brushes or mechanical commutator utilized in numerous conventional electric motors.

The manufacture of a brushless DC motor is generally similar to a permanent magnet DC motor, but may also be an asynchronous/induction motor, or switched reluctance motor. They may also utilize a neodymium magnet and be out-runners (the rotor surrounds the stator), in-runners (the stator surrounds the stator), or axial (the stator and rotor are parallel and flat).

The benefits of brushless motors over a brushed motor are high speed, high power-to-weight ratio, close to instantaneous torque and speed control (rpm), low maintenance, and high efficiency. Brushless motors find use in computer peripherals (printers, disk drives), portable power devices, and vehicles varying from automobiles to model aircraft. In current washing machines, brushless motors have enabled the replacement of gearboxes and rubber belts using a direct-drive design.

Stepper Motors

A stepper motor, also referred to as a stepping motor or step motor, is a brushless DC motor that divides a full revolution into a number of equivalent steps. The motor's position may be instructed to change and hold at one of the equal steps without using any positional sensor for feedback, as long as the motor is appropriately sized for the use in respect to speed and torque. Brushed DC motors continuously rotate when direct voltage is put on their terminals. A stepper motor is known for its characteristic of conversion of a chain of input pulses square waves to precisely defined increments in the shaft's rotational point. Each pulse spins the shaft in a fixed angle.

AC Motors

An AC motor is an electric motor powered by an alternating current (AC). The AC motor generally comprises two primary parts: an outer stator with coils energized by an alternating current to create a spinning magnetic field. An inner rotor attached to the shaft creates a second spinning magnetic field. The rotor's magnetic field could be created by reluctance saliency, permanent magnets, or AC or DC electrical windings.

Less popular, AC linear motors function on similar rules as rotating motors but they have their moving and stationary components laid out in a straight line set up, creating linear movement instead of rotation.

Application of Electric Motor

HVAC

HVAC stands for Heating, Ventilation and Air Conditioning. It is the technology for providing thermal comfort in any indoor environment such as in an office, home, or vehicle, etc.

HVAC works by providing fresh air from the outdoors. The outdoor air is air-conditioned in order to cool or heat the different areas of a building or vehicle. The conditioned air is blown into the ducts using a blower motor.

Industrial Automation

Using motors we can eliminate the use of labor or human beings. We can perform the heavy tasks with high speed and without any interruption. There is no need for involving any labor. Most of the industries run on automated machinery to work non-stop. They are also required to meet the demands of the modern world.

They are extremely efficient and having automatic control offers high production value. In short, Industrial automation is nothing without electric motors.

Benefit in Climate Change

The electrical motor does not need fuel or any other maintenance required for any engine. The use of electrical motors inside vehicles and trains allows us to use green energy or reusable energy and reduce the emission of dangerous gasses that affects public health and the ecosystem.

Agriculture

Different types of electric motors are used in agriculture to eliminate human involvement and increase productivity. They are used in every mechanical structure used in farming and agriculture.

Different kinds of machines are used nowadays to cultivate, plough soil, planting, irrigation, applying fertilizers and harvesting etc.

They are also used for cutting and packing these vegetables and fruits to meet the high demands of the market.

Compressor

An Air compressor is a mechanical device that increases the pressure of the gas by reducing its volume. An electric motor is used to pump the gas inside increasing its pressure which is then released through an outlet to do work.

Compressors are used for cleaning by releasing compressed air. It is also used for filling gas cylinders and tires. The pressurized gas can be used for cleaning objects at the micro level. It is also used in nail guns.

Blower

A blower is an equipment that increases the speed of the air or gas. It is powered by an electrical motor that pulls in the air from one side and pushes it with high speed on the other side. It is used in the exhaust system or ventilation, dust cleaning or vacuum cleaning.

Fans

Fans powered by electric motors are used for circulating air inside a room. It is also used for drying things or people. It is also used for exhausting dangerous fumes or cooling electronic components. Also, a fan plays a major role in HVAC.

Refrigeration & Air-conditioning

Air-Conditioning & Refrigeration means cooling of space. It basically works by compressing the refrigerant using a compressor that is powered by an electric motor. it is used for preserving food by maintaining the temperature below normal. It is also used to make ice from water.

Pump

A pump is used for the flow of fluid. it does not generate pressure. A pump pushes out the air creating a vacuum which is then filled up by the fluid. They are powered by electric motors which increase efficiency and save time.

Pumps are mostly used for pulling water (well pumps & submersible motors) to the surface but they are also used in industries especially in oil and gas. They are used in chemical processing industries where more smart electric pumps are used.

Component of Electric Motor

Wire is the material the current travels through. The wire is also called a conductor. Wires are typically made of copper; however, aluminum is occasionally used.

Lead wire is used to supply power to the motor from the power supply and for the winding that is wound and connected inside the motor. In English, winding is called magnet wire, which is the wire used to generate a magnetic field. In Japan, winding is also referred to as enameled wire after the enamel resin that is used as insulation material (to be described).

At present, high-polymer materials are used for insulation, but habitual naming criteria of enameled wire are still used.

As a component of motor winding, the term "enameled wire" is used in Japanese. Enameled wire is referred to as magnet wire in English.

(Iron) core is the path for flux and is made of iron as the name (iron) core suggests. Moreover, a core used to combine two magnets with flux is called a yoke.

Iron for mechanical structures and that for cores contain different types of accessory ingredients. Iron for mechanical structures contains carbon (C), while iron for cores is mixed with silicon (Si) and called silicon steel. In the case of a motor, the core is divided into the stator core and the rotor core, and a magnetic circuit is configured through the air gap in between. Since the magnetic pole of the stator core configuring the magnetic circuit of electromagnetic field DC motors is excited by direct current, the core does not need to be laminated; soft steel is used instead.

On the other hand, laminated core is used for a rotor core configuring the armature circuit as the flux changes with rotation. Also, permanent magnets are often used for the magnetic pole of small DC motors. Cores for the stator of synchronous motors and the stator and rotor of induction motors are excited by alternating current, therefore laminated core is used for each of them.

Insulators prevent electric current from flowing to any locations other than the desired one, and materials that have such characteristics are called insulating materials.

Rubber, enamel, and other high-molecular compounds or resins, paper, mica, glass fiber, etc. are used as insulators.

Among materials that make up a motor, a permanent magnet is important as it generates magnetic fields. Permanent magnets can be said to be a type of iron-based alloy or oxide.

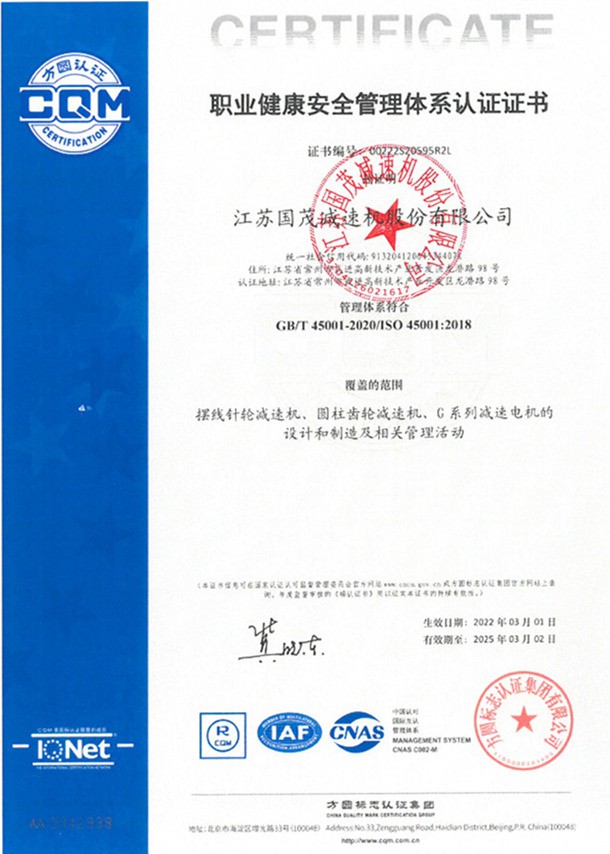

Certifications

Frequently Asked Questions

We're professional electric motor manufacturers and suppliers in China. We warmly welcome you to wholesale high quality electric motor made in China here from our factory. For customized service, contact us now.

mpve helical optimum precision planetary reducer, mpvb helical optimum precision planetary reducer, gearbox for rubber machinery