Guomao Group has been a manufacturer specializing in power transmission industry for 30 years with a wide product series including speed reducer boxes, gear motors, electric motors and become a bellwether in the intelligent automation.

Wide Range of Fields

We have established business relationship with leaders in various fields such as energy, mining, construction, logistics, pharmaceuticals, chemicals, machinery and robotics.

Wide Range of Applications

Our products are widely used in Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction works, Energy & Mining, Food & Beverage Shops, Hotels, Building Material Shops, Farms, Restaurant, Home Use, Retail, Food Shop, Advertising Company, Energy & Mining, Other.

Quality Assurance

Each batch of goods has a corresponding quality inspection report to solve your concerns about product quality.

Quick Transportation

We cooperate with professional sea, air and logistics companies to provide you with the best transportation solution.

What Is Precision Planetary Reducer

The reducers are composed of a gearbox and aligned input and output shafts. Industrial automation systems, including DC transmission, servo, and stepping systems, use planetary gear reducers to efficiently manage tasks that demand high levels of torque. If you want to know the specifications and prices of Precision Planetary Reducer, please contact us!

Greater Power Transmission Efficiency

The gearing arrangement of the planetary gear motor results in greater power transmission efficiency. This arrangement transfers maximum input energy to the desired output. That way, you can achieve greater power transmission efficiency when compared to traditional gearbox solutions. Furthermore, the system has a higher power transmission capability with lower inertia that suits many industrial applications. The need for fewer power drives desired efficiency at each stage.

Compact and Efficient Load Distribution

The Planetary Gearbox has found widespread applicability for cutting-edge technologies like robotics and 3D printing. The machine design is such that it spreads the power evenly through multiple gears to achieve high torque within a small space. Furthermore, the driving member and the driven equipment are in the same line, which results in a space-saving solution. This gearing arrangement will also provide better stability.

Light-Weight and High-Power Density

Do you imagine industrial gearboxes as bulky machines? Not with modern planetary gearboxes. They are lightweight when compared to traditional Industrial Gearboxes and have higher torque transmitting capacity. This torque transmitting capacity can be further increased by adding the number of planet gears.

While buying a gearbox, you must consider power density as a criterion. It describes how quickly the machine can transfer energy. As mentioned above, a planetary gearbox doesn't have a single gear but uses multiple gears to share the load. This results in high power density and enhances transmission efficiency.

Accurate Results & Stability

A planetary gearbox offers reliability and stability because of the even power distribution and rotational stiffness. The machines are also stable as there is no lateral pressure on the gear teeth, and the power is transmitted radially. In traditional industry gearboxes, the loading concentration is central. This may result in the slower transmission of power. In the case of planetary gearboxes, the structure minimizes elastic deflections that result in durability. Furthermore, the machine design provides a high proportion of input energy that works seamlessly with other gear arrangements for accurate results.

Enhanced Life-Span

If you are looking for an industrial gearbox solution that offers durability, a planetary gearbox is ideal. The unique and modular design of the machine offers several advantages for high-duty applications. With the absence of a pinion bearing, the equipment becomes resistant to damage from high-torque operations. Moreover, the multiple gears contacting surfaces ensure long life when compared to a traditional gearbox with a similar load capacity.

Types of Precision Planetary Reducer

Output Shaft

An output shaft is coaxial or parallel configured with the input shaft. There are several forms of output shaft to choose from, for example, usually the output shaft with a feather key, which can make the connection quick and safe between speed reducer and the machinery. In addition, there are smooth shafts or spline shafts on which additional driving parts such as pulleys, gears and sprockets can be installed. The output shaft type planetary speed reducer has a wide range of applications and is suitable for almost all kinds of automation or machinery and equipment. Such as machine tool, lathe, milling machine, water jet cutting machine, laser cutting machine, bottle blowing machine, rubber and plastic machinery, packaging machinery, CNC metal processing machine automatic loading and unloading automatic gantry robotic arm and so on.

Flange Type

The output flange is designed according to ISO 9409 specification, which can be combined with various pinions and pulleys or couplings that meet this specification to easily and quickly connect to the applied machinery and equipment. The flange type planetary speed reducer can provide higher torsional rigidity due to the structural design and the large diameter of the output flange, and is especially suitable for constantly changing motion control applications. Commonly used in delta robotics or rack and pinion drives.

Right Angle Type

The right angle planetary speed reducer has a right angle housing, which turns the output torque and speed of the servo motor at 90 degree. It helps to save installation space and make the overall design of the equipment more compact. The output end of the right angle planetary gearbox also has two types to choose from - output shaft or flange type. The gearbox can be installed in any direction, which greatly increases the flexibility of design and installation. It is often used in automation devices driven by servo motors, panel handling, automatic storage systems, robotic arms, pipe bending machines, automated guided vehicles (AGV), etc.

Customized Models

Sesame Motor has been focusing on the design and manufacture of motors and speed reducers for decades. Our well-trained and experienced engineers and flexible manufacturing capabilities are able to develop exclusive drive solutions together with customers. Whether it is a special application environment, high output power or rigidity, or special requirements in surface treatment or materials, we can design and manufacture according to your specifications, while meeting the performance, quality and cost standards you expect.

Application of Precision Planetary Reducer

In the realm of robotics and automation, precision planetary gearbox are commonly used to drive robotic arms, grippers, and other essential components. Their compact size and high torque capabilities make them ideal for delivering precise movements in industrial robots, increasing accuracy and overall efficiency in various manufacturing processes. Whether it's pick-and-place operations or intricate assembly tasks, these gearboxes ensure smooth and repeatable motions, contributing to optimized manufacturing workflows.

In the field of machine tools, precision planetary gearboxes are employed in spindle drives and feed drives. With the ability to handle high-speed rotation and deliver consistent torque, these gearboxes enable metalworking machines like lathes, milling machines, and CNC routers to perform complex cutting, shaping, and milling operations with unmatched precision. As a result, the quality of finished products improves, reducing waste and increasing productivity.

In the packaging industry, precision planetary gearboxes find wide application in various packaging machines, such as form-fill-seal (FFS) machines, cartoners, and labelers. These gearboxes facilitate the smooth operation of conveyors, augers, and sealing mechanisms, ensuring precise and synchronized movements to create well-packaged products. The high gear ratios offered by planetary gearboxes help adapt to different packaging formats and sizes, making them versatile choices for packaging lines.

The aerospace and defense industries demand high-performance gear solutions capable of withstanding extreme conditions. Precision planetary gearboxes are commonly employed in aircraft actuators, satellite solar panel deployments, and unmanned aerial vehicles (UAVs). Their lightweight design, reliability, and high power-to-weight ratio make them well-suited for such critical applications. Furthermore, these gearboxes contribute to reducing maintenance requirements and extending the lifespan of aerospace systems.

In warehouses, distribution centers, and manufacturing facilities, precision planetary gearboxes are integrated into various material handling equipment, such as conveyor systems, stackers, and forklifts. These gearboxes ensure efficient power transmission, allowing for smooth acceleration, deceleration, and direction changes. The precision and repeatability of movements improve overall throughput and reduce the risk of product damage during handling processes.

The renewable energy sector, particularly wind and solar power, benefits from the application of precision planetary gearboxes. In wind turbines, these gearboxes enable the conversion of low-speed, high-torque rotational motion into high-speed rotation for electricity generation. Similarly, in solar tracking systems, precision gearboxes ensure optimal alignment of solar panels with the sun, maximizing energy capture and enhancing system efficiency.

Component of Precision Planetary Reducer

Sun Gear

It is an essential component of the planetary gearbox and plays an important role in the function of the gear system. This gear is located at the center of the gear system and is surrounded by multiple gears. This gear is smaller in size compared to the other gears as it meshes with the teeth of the gears for smooth and efficient power transmission.

Its main function is to control the speed and direction of the shaft and act as a central point of the gearbox.

Planet Gear

An important function of planet gear is to provide gear reduction. It has several teeth that surround its circumference. These teeth mesh with the teeth of the sun gear and cause the rotation of the output shaft.

The ratio of the number of teeth of planetary gear and sun gear determines the gear reduction ratio. This ratio is important to achieve high torque at a small size as compared to other gear systems.

Ring Gear

The ring gear is a large circular gear that acts as a stationary component of a planetary gearbox. It is made up of steel and is responsible for transmitting the power from the input gear to the output shaft.

The design of the ring gear contributes to the reliability and durability of the gearbox. Its high-strengthened steel construction helps the gearbox to withstand in high torque and shock load conditions and makes it suitable for heavy-duty applications.

Mechtex 62P Planetary Gearbox is 62mm Planetary Gearbox with Metal Gears. It has 12Nm to 65Nm Gear Torque and up to 938.85 Gear Ratio. It can combine with various types of motors and is suitable for heavy-duty applications.

Carrier

It is another important component of the planetary gearbox. It is a cylindrical structure with holes that hold the planet gear and allow it to rotate around the sun gear. It not only holds the planet gear but also helps in evenly distributing the load on other gears.

It is a crucial component for the smooth and efficient operation of the gearbox without a single gear burnt with load.

Input Shaft

It receives the power from the motor and transfers it to the gears of the planetary gearbox to determine the output speed and torque of the gearbox. It also helps to evenly distribute the load among all the gears.

Output Shaft

It is located at the end of the planetary gearbox and connected with the final drive or gears. It is made up of high-strength materials to ensure smooth operation and efficient power transmission.

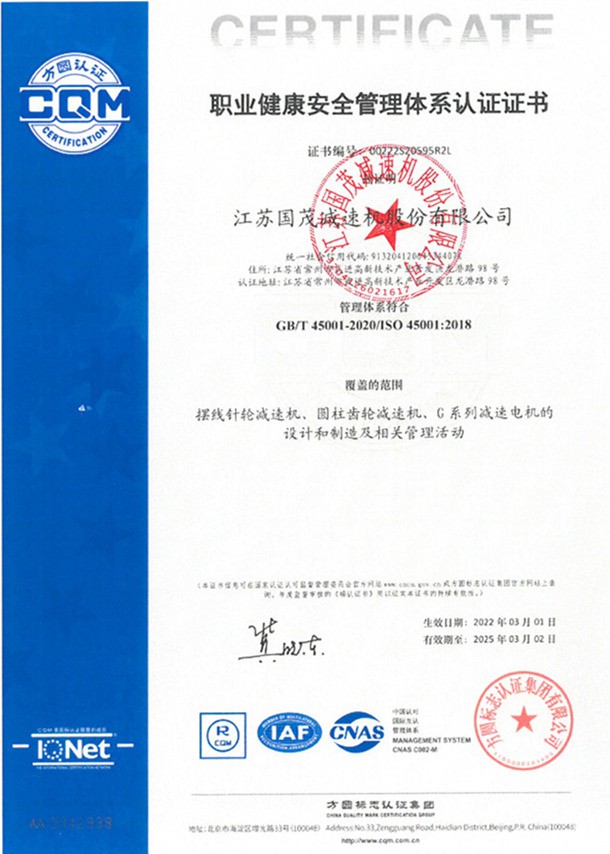

Certifications

Frequently Asked Questions

We're professional precision planetary reducer manufacturers and suppliers in China. We warmly welcome you to wholesale high quality precision planetary reducer made in China here from our factory. For customized service, contact us now.

gmy gmx center drive mill gearbox, servo motor, permanent magnet synchronous motor