Guomao Group has been a manufacturer specializing in power transmission industry for 30 years with a wide product series including speed reducer boxes, gear motors, electric motors and become a bellwether in the intelligent automation.

Wide Range of Fields

We have established business relationship with leaders in various fields such as energy, mining, construction, logistics, pharmaceuticals, chemicals, machinery and robotics.

Wide Range of Applications

Our products are widely used in Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction works, Energy & Mining, Food & Beverage Shops, Hotels, Building Material Shops, Farms, Restaurant, Home Use, Retail, Food Shop, Advertising Company, Energy & Mining, Other.

Quality Assurance

Each batch of goods has a corresponding quality inspection report to solve your concerns about product quality.

Quick Transportation

We cooperate with professional sea, air and logistics companies to provide you with the best transportation solution.

What Is Speed Reducer Gearbox

Speed reducers, also known as gearboxes or gear reducers, are enclosed mechanical devices that use gear trains to enhance the torque and lower speeds on a drive between a motor and a piece of machinery. If you want to know the specifications and prices of Speed Reducer Gearbox, please contact us!

Torque Multiplication

For devices that require rapid acceleration, the importance of torque can't be overstated. To achieve this, gear reducers are one of the best options, as they can exponentially increase torque based on the number of gears in the system and the number of teeth in each of these gears. For example, an engine with a torque of 100 lb-in can increase its torque fivefold by using a gear reducer with a 5:1 reduction ratio.

Speed Reduction

In many gear reducers, the increase in torque is inversely proportional to the speed. Thus, in systems where there is a requirement for rapid speed reduction, these devices can turn out to be extremely useful. Just like the increase in torque, the decrease in output speed can also be determined using the reduction ratio.

Inertia Reduction

In order to deal with size constraints, many motors are designed to generate more torque than is acceptable for their frame size. As a result, the load inertia might increase significantly, leading to an increase in settling time for a motor, consequently reducing its efficiency. This inertial mismatch can be easily handled by a gear reducer. A gearbox system with a relatively low gear ratio can significantly reduce load inertia, as it is proportional to the inverse square of the gear ratio.

Economical

In order to achieve high torque, low speeds, and an increased capability to handle inertial loads, manufacturers require significantly large motors, which are difficult and expensive to make. Conversely, gear reducers can achieve all these goals with a much smaller motor, thereby driving down the cost of production.

Cost Reduction

Instead of buying an expensive high powered motor, the existing motor can be combined with a speed reducer to achieve the required output power, this reduces the costs of the overall configuration.

Protection of the Motor

When the machine is in operation, the speed reducer will be the first component to be damaged due to overload, to prevent the motor from high loading and damage directly. Moreover, the cost of repairing or replacing the speed reducer is relatively low, which can also reduce maintenance costs.

Energy Saving

Without a gearbox, the motor may run at a lower speed and generate heat that may damage the motor, in order to meet the required torque. Lower rotation speed will result in current rise significantly and consume more energy, therefore, the use of a speed reducer can significantly help to reduce energy consumption and to avoid damage to the motor.

Types of Speed Reducer Gearbox

Single Reduction Gearbox

The single reduction gearbox features only one set of gears. It incorporates ports for the propeller shaft and motor shaft to enter the assembly. A small gear, known as the pinion, is driven by the drive motor shaft. As the pinion receives power from the drive motor, it further drives the large gear, directly coupled to the propeller shaft. Typically, the large gear has double the size of the pinion.

Double Reduction Gearbox

Used in high-speed conditions, the double reduction gearbox has a pinion on the input shaft connected to the first gear. The first gear is then linked to another shaft with the low-speed pinion. This pinion is fixed to the second deceleration section, directly linked to the drive shaft, achieving a speed reduction of up to a 20:1 ratio.

Magnetic Speed Reducer

The magnetic speed reducer, an unconventional alternative to traditional reducers, utilises magnetic attraction force instead of physical contact between rotating parts for speed and torque control. Although less common due to their high weight, low torques, and complex design, these gearboxes require minimal maintenance, as they do not need lubrication and can operate at high temperatures.

Parallel Shaft Reduction Gearbox

Comprising multiple gear assemblies, the parallel shaft reduction gearbox enhances reduction capacity. The overall gear reduction ratio is determined by multiplying the ratios of individual gears in each assembly. For example, if the gearbox contains 7:1, 6:1, and 5:1 sections, the overall ratio is 210:1.

Planetary Gearbox

The planetary gearbox's gear ratio is based on the number of teeth on the sun gear and ring gear. The planetary gear acts as an idler gear, not affecting the gear ratio. The total number of teeth determines the planetary gear ratio on the sun and ring gear divided by the number of sun gear teeth.

Right-Angle Worm Reduction Gearbox

The gear ratio of the right-angle worm reduction gearbox depends on the threads of the worm and the number of teeth on the mating worm wheel. For instance, if the worm has 3 threads and the attached worm wheel has 48 teeth, the output gear ratio is 16:1.

Helical Gearbox

Helical gearboxes feature gears locked at 90 degrees and are commonly installed in overlapping or parallel positions. Overlapping gearboxes have lower load capacity compared to parallel gearboxes but generate less noise. They are ideal for systems requiring high torque and speed, offering low maintenance and cost-effective performance.

Reduction Gearbox Ratio

To calculate the gear ratio or "reduction gear," simply divide the number of teeth on the larger gear by the number of teeth on the smaller gear. Let's illustrate this with an example:

Imagine a scenario where a 60-tooth large gear meshes with a 10-tooth pinion gear driven by an electric motor or engine. In this case, the resulting gear ratio is 6:1 (60/10 = 6/1).

If the engine initially runs at 3550 rpm, the gearbox decreases this speed by a factor of 6, resulting in a speed of 591.66 rpm (3550/6). Simultaneously, suppose the engine produces a torque of 15 lb. in. In that case, the reducer gearbox augments this torque by a factor of five, reaching 75 lb. in, before accounting for any transmission efficiency losses.

How can the Operation of Gear Motors be Improved?

The Analysis and Correction of Mechanical Noise Levels

Gear motors should be subjected to tests using frequency measurement equipment before their release on the market. It is very important to take note of mechanical vibrations and for your gear motor supplier to know how to use vibration measurement instruments to prevent uncomfortable frequencies.

Optimal Torque Measurement

The optimal measurement of the starting torque, output torque and rated torque guarantees the proper transmission of the motion and the adaptability of the machine or application.

Power consumption

Energy efficiency of the speed reducer is another item to keep in mind when choosing one model or the other. The disposition of the gear train, the disposition and characteristics of rolling bearings or the surface treatments of components enhance performance across the entire system.

Service Life Tests

Tests are carried out in laboratories to measure the resistance, limits and the speed reducer service life. Gear motor suppliers that have these laboratories and the testing technologies they offer can guarantee buyers the delivery of quality gear motors.

Speed Reducers Design

Before delving into the particulars of gear motor design, we will mention the service factor, which is a reference to the conditions that affect or increase the power demands of a gear motor. This factor may be related to dust and relative humidity, the amount of vibration to withstand, or the quantity of operation cycles, among other factors. Reducing the influence of the service factor is the result of having a deep knowledge of the inner workings of the reducer and improving the design of its entire transmission mechanism.

After studying the operation to be carried out, gear motor manufacturers can design a transmission system that optimises output power. Here you can find some technical elements which may prevent loss of energy, thereby increasing the motor's lifespan.

Some examples would be

Use and placement of rolling bearings: Within geared systems, the use of rolling bearings offers a reduction of friction between the many moving parts, thus considerably reducing loss of energy.

Use of self-lubricated plain bearings: This type of parts reduce friction to a lower extent than rolling bearings do. Still, they minimise loss of resilience to axial motions.

Gear design (tooth size, placement…): Spur gears placed on parallel axes are the type of gear that produce the least loss of efficiency. Several modifications can be made to the teeth to increase their efficiency, but it will depend on each specific case.

Use of vibration-limiting components: Several solutions can be applied to reduce vibrations, such as the use of rolling bearings, washers, plain bearings… Application of all of these items will improve the proper operation of the gear motor in the long run. It will be more precise, less noisy, and will suffer less wear as a result of limited vibration levels.

Importance of Materials and Lifespan

In addition to the design, the quality of materials and specific treatments that each part is subjected to will likewise lengthen its resilience and lifespan. Here, for example, there are treatments that are capable of increasing the thermal resilience of parts to increase their heat dissipation inside a gearbox.

Speaking about the inherent characteristics of material, it is advisable to always have present the requirements of the application (number of stages, r.p.m., output power, etc.) so as to choose the material which performs optimally within each project.

There are several materials that may improve a gear motor's efficiency, such as self-lubricating or low-friction plastics. These types of materials increase efficiency but diminish lifespan. Each particular case should be studied to determine which material is to be more beneficial in relation to workloads and other aspects.

When working with metals, we can apply treatments for metal materials to increase the hardness and resilience of parts, and to protect them against external agents. These types of treatments do not prevent loss of energy between gears, but they can drastically increase the parts' lifespan.

How to Choose peed Reducer Gearbox

Requirements For Selecting a Gear Reducer

Several variables must be considered when purchasing a gear reducer. A gear reducer is often used to modify the properties (torque as well as speed) of a mechanism's input and output axes. This is why you must be aware of the torque plus rotation speed.

As a result, the torque should be the first question you ask yourself. A reducer boosts your motor's torque, allowing a receiving part to spin under the influence of a new torque. Manufacturers of gear reducers may mention the minimum and maximum torque (measured in newton meters, N.m) that each of their devices can sustain. The torque strength varies depending on the gear reducer. Planetary gears, for example, have quite a high torque intensity.

Another function of a gear reducer is to lower motor speed, and we suggest that you consider the optimal reduction ratio for your application. The reduction ratio is utilized to calculate the output rotational speed depending on the speed of rotation of your motor. Manufacturers also provide this information on their product sites. It's measured in rotations per minute.

Finally, consider what type of gear reducer component is most suited to your application. Your gear reducer's input and output shafts might be coaxial, parallel-shaft, as well as orthogonal. This is determined by your intended usage.

The Different Kinds of Gear Reducers

Planetary gear reducers, worm gear reducers, gear train gear reducers, plus bevel gear reducers are the four primary kinds of gear reducers. Every gear reducer has benefits and drawbacks. You must choose the one that is most suited to your intended usage.

For example, if you want to maximize efficiency, you should pick a planetary gearbox or parallel Helical Gearbox instead of a bevel gear reducer.

When Should a Planetary Gearbox Be Used?

The coaxial assembly is one of the most distinguishing features of a planetary gearbox. Planetary gearboxes are small because of this sort of arrangement.

Planetary gears have many benefits, including their small size, great efficiency, minimal clearance, with high torque to weight ratio. Their intricate and pricey design, on the other hand, need specialist upkeep.

Planetary gears are recommended for applications demanding fast accelerations (robotics) as well as those requiring low-speed yet high torque (industrial rotary furnaces). They are also commonly employed in machining centers as well as other machine tools, as well as mobile gear for public and agricultural operations.

When Should a Worm Gear Reducer Be Used?

Worm gear reducers feature input and output shafts that are perpendicular to each other. They are often employed in situations that need an extremely high transmission ratio.

Worm gear reducers have a non-reversible mechanism. This indicates that the worm cannot be driven by the worm wheel. The benefit of this non-reversible technique is that it provides the system with a higher degree of security.

Worm gear reducers are far less costly and quieter than planetary gearboxes. Worm gear reducers don't really vibrate, thus they are quieter and more pleasant to operate.

Worm gear reducers also have a varying amount of performance. You may increase the performance of your worm gear reducer by combining it with additional gearboxes as well as gear trains. This sort of technology is recommended for conveyors, winches, and handling.

When Should a Gear Train Gear Reducer Be Used?

Gear train gear reducers having parallel shafts are often utilized in high-power applications such as conveyors. Because of the ease of their technology, you will be able to save money on maintenance. Furthermore, gear train gear reducers have an extremely high-performance level, close to 1. Each gear train has a low reduction ratio.

When Should a Bevel Gear Reducer Be Used?

The fundamental feature of bevel gear reducers is its angular bell crank, which enables the operator to adjust the machine's rotation scheme. This allows you to go from a transversal rotation system to a longitudinal rotation system.

Bevel gear reducers are small in size. They are quite strong and can endure a lot of force. Because of the power of their teeth, they may be used with three-phase asynchronous motors, as well as synchronous or asynchronous servomotors.

Their performance level, however, remains lower than that of planetary gearboxes. Bevel gear reducers are also exceedingly costly and demanding to maintain.

Bevel gear reducers are often found in high-powered conveyors, but they are also found in mobile equipment used in agriculture or public works.

Measuring the Dimensions of Your Gear Reducer

To determine the size of your gear reducer, you must first choose the proper shaft. There are three shaft orientations to choose from: orthogonal, coaxial, plus parallel.

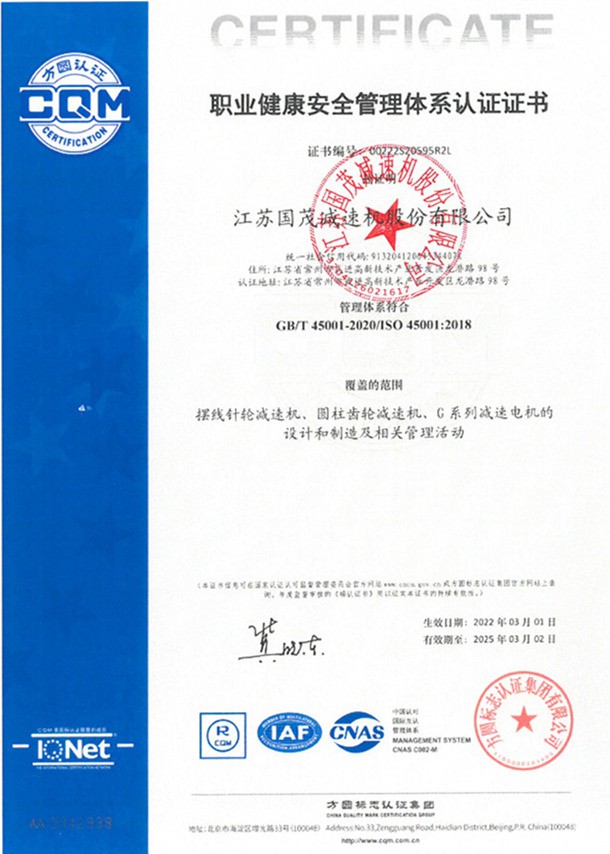

Certifications

Frequently Asked Questions

We're professional speed reducer gearbox manufacturers and suppliers in China. We warmly welcome you to wholesale high quality speed reducer gearbox made in China here from our factory. For customized service, contact us now.

variable frequency ac electric motor, gmlx gmls vertical mill gearbox, nmrv worm gearbox speed reducer motor